Cleanroom Resin Flooring in Bacup

Enquire Today For A Free No Obligation Quote

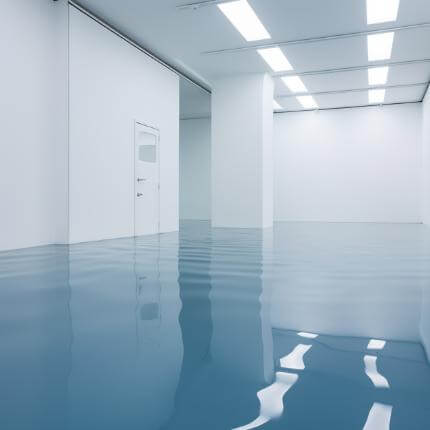

At Cleanroom Resin Flooring, we deliver high-performance, contamination-controlled flooring systems designed for regulated environments in Bacup and throughout the UK. Our floors are engineered to support particle-sensitive operations, withstand stringent sanitation routines, and maintain the seamless, non-porous surfaces required for controlled manufacturing and research spaces.

Whether your facility includes ISO-rated cleanrooms, sterile laboratories, pharmaceutical suites, or specialist containment areas, Cleanroom Resin Flooring provide compliant installations tailored to operational standards and environmental demands.

What Is the Cost of Cleanroom Resin Flooring in Bacup?

The cost of cleanroom resin flooring in Bacup ranges from £60 to £120 per m², depending on the selected resin system, the size of the installation, and the level of cleanliness and technical performance required.

Costs may increase with features such as ESD control, hygienic coving, high-grade slip resistance, chemical-tolerant formulations, or fast-cure systems needed for sensitive areas.

Contact Cleanroom Resin Flooring in Bacup to get customised prices for installing resin flooring at your facility.

How Does Cleanroom Resin Flooring Enhance Controlled Environments in Bacup?

Cleanroom resin flooring in Bacup provides a seamless, non-absorbent surface that prevents particle buildup and supports strict sanitation protocols.

These systems resist disinfectants, solvents, and laboratory chemicals while offering long-term durability under foot traffic, trolleys, and equipment loads. Options for ESD protection, anti-microbial finishes, and low-VOC formulations in Bacup help maintain compliance and environmental stability.

Which Resin Systems Are Typically Installed in Cleanrooms Across Bacup?

Facilities in Bacup that operate controlled environments rely on several resin flooring systems suited to sterility, hygiene, and precision requirements, including:

- Epoxy flooring – Smooth, chemically resistant finishes ideal for laboratories and general clean zones.

- Polyurethane (PU) systems – Flexible, thermally stable surfaces suited to containment rooms and high-stress technical areas.

- MMA (methyl methacrylate) systems – Rapid-curing solutions for sites in Bacup needing fast turnaround times.

- Specialist cleanroom finishes – Custom colours, ESD protection, and surface textures meeting specific compliance and operational needs.

Is Specialist Surface Preparation Included with Cleanroom Resin Flooring in Bacup?

Cleanroom resin flooring services in Bacup include full substrate preparation, such as moisture assessment, mechanical grinding or shot blasting, and appropriate priming for strong adhesion.

Installation is completed as a seamless monolithic layer, preventing gaps where particles or microbes could accumulate. Integrated coving is available in Bacup to create smooth wall-to-floor transitions for enhanced cleanability.

How Long Does It Take to Install Cleanroom Resin Flooring in Bacup?

Most cleanroom resin flooring installations in Bacup require 2 to 5 days, depending on the system type and operational constraints.

MMA formulations can cure in under 24 hours, supporting rapid reinstatement of controlled environments in Bacup. Flexible schedules, including phased works and off-peak installation, are available for active facilities.

What Compliance and Performance Requirements Must Cleanroom Resin Flooring Meet in Bacup?

Cleanroom resin floors in Bacup must meet stringent criteria, including seamless finishes, low particulate emission, and strong resistance to disinfectants and solvents.

Compliance may align with ISO cleanroom classifications, BS 8204-6, and facility-specific protocols requiring PTV-rated slip resistance, ESD control, or anti-microbial protection for sterile operations in Bacup.

Which Areas Within Controlled Facilities in Bacup Commonly Use Cleanroom Resin Flooring?

Cleanroom environments in Bacup use resin flooring across a wide variety of controlled and technical spaces, including:

- ISO-rated cleanrooms – Particle-controlled surfaces that are seamless and easy to sanitise.

- Sterile laboratories – Chemically resistant finishes for spill-prone testing zones.

- Pharmaceutical suites – Hygienic, durable floors supporting sterile workflow.

- Containment and biohazard areas – High-performance surfaces built for chemical and mechanical stress.

- Air-lock and gowning rooms – Smooth, precise finishes for contamination control.

- Technical corridors – Robust systems designed for trolley movement and equipment transport in Bacup.

- Plant and service rooms – Impact-resistant finishes for HVAC and filtration support spaces.

- Washdown or disinfection zones – Slip-resistant, waterproof flooring for cleaning-intensive areas.

Can Cleanroom Resin Flooring in Bacup Be Adapted for ESD Control or Visual Zoning?

Cleanroom resin flooring in Bacup can be customised with ESD-controlled formulations, colour-coded pathways, and slip-resistant textures to suit sensitive operations.

Options include conductive or static-dissipative layers, safety demarcation lines, and finishes tailored to specific cleanliness or regulatory requirements.

Contact Cleanroom Resin Flooring in lancashire for guidance on achieving compliant flooring throughout your cleanroom environments.

Find More Info

Make sure you contact us today for a number of great cleanroom resin flooring services in North West.

Here are some towns we cover near Bacup OL13 9

Rawtenstall, Haslingden, Burnley, Ramsbottom, RochdaleFor more information on Cleanroom Resin Flooring in Bacup OL13 9, fill in the contact form below to receive a free quote today.

★★★★★

The flooring has made a noticeable improvement to the cleanliness and control within our cleanroom areas. It’s incredibly easy to sanitise, and the seamless finish has helped reduce particle risks during our daily operations.

Elena Wintrell

Lancashire

★★★★★

The team handled the installation professionally and understood the strict requirements of our controlled environment. The resin floor feels robust, hygienic, and perfectly suited to our pharmaceutical production workflows.

Jonathan Pellam

Lancashire